Energy Management System (EMS) Design

Most design and mechanical engineers understand office buildings, factories, warehouses, etc. GROCERY on the other hand is unique! Many of the traditional design aspects change as the systems need to work together. If they don’t, energy is wasted and the Grocery Store is not operating at maximum performance.

Tell-tale signs include:

- Condensation on the refrigerated case doors,

- Ice on the evaporators,

- Water on the floor,

- Heaters running in the dead of summer,

- Doors that won’t shut properly,

- Customers complaining it’s too cold

- Garbage cans littered with food waste,

- Etc.

All of the above are results of poor design, poor engineering and poor maintenance. The best measures to prevent the above is to take steps up front to prevent these from happening. There are lot of design criteria improvements to consider that Singh360 can help with.

- Are you designing the building for maximum operating conditions but your systems run seventy percent of time under other conditions? → Not efficient!

- Are HVAC, Lighting and Refrigeration systems designed by different groups? Yet these are very inter-dependent systems, meaning they must be designed to work in harmony with each other. → How will that work?

- Are HVAC vents pointed at refrigerated cases? Are HVAC sensors too close to refrigerated cases? → A guarantee they will fight each other.

- Do HVAC units for the store have economizers on them? This is very problematic with large de-humidification systems.

- Are you maintaining the relative humidity in the store? …when you should be controlling to dew point?

At Singh360 we design the controls for your application. We influence the design criteria and can help the mechanical designer be more effective through our controls. We offer a full design service of the controls, from CAD drawings, to system selection, programming, implementation, to the finished As-Built drawings.

Things to consider:

- Do you think designing a ‘green building’ costs more?

- Do you understand the value in case controls versus the more traditional circuit controls for your refrigerated cases?

- Are you selecting the best available options for air-conditioning and refrigeration equipment?

- Are you executing your design so your store comes in under budget. This is usually always applauded, but are you sacrificing the ongoing operational costs? You only build once with your capital budget, but pay year after year to operate the store out of your operational budget. Understanding the difference is vitally important.

- Are you certain each company in your team knows what’s expected of them?

The utility costs in electricity, gas and water could be 3-4 times higher in the next 5-10 years, which should impact your design plans. At Singh360, we believe in designing the controls for your mechanical, electrical, plumbing and refrigeration based on science. We evaluate many design options before finalizing and recommending one system.

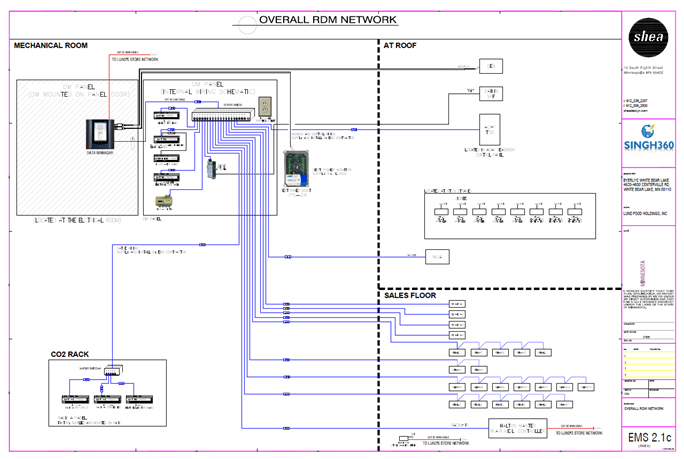

Not only do we assist in the design phases, we develop CAD drawings, build a responsibility matrix for each project and finish up with as-built drawings that are posted for any service company to understand when servicing your account.

Typically a set of EMS CAD drawings from Singh360 can be comprised of up to 40-50 CAD sheets, depending on the size and complexity of the job. Below is an example of one of the sample pages from the set of drawings by Singh360.