Energy Conservation & Savings

Singh360 is all about making your operation more efficient, which brings about an economical benefit. This can be done by making sure your existing equipment is up to par and is working effectively. But secondly, there are improvements that can be made that will bring about additional benefits. We have performed many of these improvements and show our customers very good payback periods.

Energy Management System (EMS) Retrofit – At some point an EMS system becomes more costly to maintain and keep alive than it’s worth. The decision to retrofit in a new system might be caused by:

- A vendor goes out of business and parts are unavailable

- The version you have may be old and is no longer supported by the manufacturer

- Major portions failing, which disable certain system functions. This might include the front end screen, the remote connectivity or controllers burning out.

- New better features becomes generally available, but can’t be implemented on your system.

What ever the reason, Singh360 is there to assist you. We done entire refrigeration control system swap outs while the store remains open and without losing a pound of food! This requires a lot of planning and meticulous execution.

It doesn’t matter if your using CPC, Danfoss, RDM or any of the other systems. We have the experience to help you get the job done.

Refrigeration Energy Measures – Refrigeration systems for grocery stores get complex quickly. But with the complexity comes opportunities to fine tune the system and make the operate better and more economically, if you know what you’re doing!

Floating Suction Pressure – Most refrigeration rack systems are designed to main a particular suction pressure to get cases to prescribed temperatures. Some racks have a single suction group, but it’s very common to have 2 suction groups and sometimes even 3. A proper control system can manage these. But, the control systems usually maintains a pre-set suction pressure and turn a combination of compressors/unloaders on and off to maintain it. When all cases/circuits are satisfied and running well, keeping the suction pressure at the dialed in setting can become wasteful. Floating the pressure upwards at the right time, will off load the refrigeration rack, causing compressors to turn off, because they are no longer needed to maintain the lower set point. But when do you float them up? That is the prime question! This can occur many times during a day and knowing when to float and when not to float is critical. The engineers at Singh360 can help!

Floating Discharge Pressure – The cooling of the refrigerant through the condensers obviously works better in winter than in the summer, when the temperature differences are higher. When the temperature difference is greater, the head pressure of the rack system can be floated. By lessening the compression ratio on the rack, the compressors will run more efficient. But when do you float discharge pressure? That is the prime question! This can occur many times and knowing when to float and when not to float is critical for energy savings. The engineers at Singh360 can help!

Condenser VFD – Condensers are usually made up of a heat transfer coil and several condenser fans pushing outside air through the coil to cool off the hot refrigerant. Depending on the heat transfer rate and discharge pressure, condenser fans are turned on and off as they are needed. Rather than stage these fans on and off, a Variable Frequency Drive (VFD) on the condenser motor bank can operate all fans from 0-100%. Base on Affinity Law, the electrical power is directly proportional to the speed of the motor that drives it. A 10% slow downin the condenser fans from the VFD, reduce the energy draw by 27%. A 25% slow down reduces the energy draw by 58%. The key is know when this is applicable and when can it be done. The engineers at Singh360 can help!

Compressor VFD – A refrigeration rack is made up of multiple compressors that are staged on and off to meet a prescribed suction pressure. Some compressors even have unloaders to provide additional stages. These are designed by the rack manufacturers to dialed in the suction pressure better. Never-the-less, steps are created by sequencing these compressors and unloaders. These steps are not small, which create swings in the suction pressure. Rather than turning compressors on and off, a VFD can vary the output providing for energy savings and a longer life of the compressor. Many questions are before you:

Compressor VFD – A refrigeration rack is made up of multiple compressors that are staged on and off to meet a prescribed suction pressure. Some compressors even have unloaders to provide additional stages. These are designed by the rack manufacturers to dialed in the suction pressure better. Never-the-less, steps are created by sequencing these compressors and unloaders. These steps are not small, which create swings in the suction pressure. Rather than turning compressors on and off, a VFD can vary the output providing for energy savings and a longer life of the compressor. Many questions are before you:

- Do you put a VFD on the lead compressor or on multiple compressors?

- When do you throttle and when don’t you?

The engineers at Singh360 can help!

Glass Door Retrofit – Many refrigerated cases are wide open, to allow the shopper to see what they are buying and to allow them to reach for their food without any hinderances. Marketing people like this, but they don’t have to pay the electric bill! Depending on the style of the case, glass doors can be retrofitted on to the frames. These are usually double paned and self closing, which can bring the grocer a reduction in refrigeration needs of up to 80%.The benefits are numerous:

- A reduction in refrigeration load – rack runs less!

- A more comfortable environment for the shopper – no longer so cold in the store.

- Higher food quality and freshness

- Good environmental and sustainability effects

Let Singh360 help you determine if your cases are adaptable and able to be retrofitted.

Night Curtains – When glass doors are not conducive to being installed on open refrigerated cases, or the budget isn’t there to do it, ‘Night Curtains’ can be used. These are made of an aluminum mesh material that is drawn closed when the store closes to shoppers at night to save energy. When drawn, the food in the cases are shielded from the ambient temperatures and light of the store. A deployed night curtain will therefore reduce the refrigeration needs and off load the rack compressors, to save you money. The benefits are numerous:

- Improve product integrity

- Increase energy efficiency & case performance

- Lower utility bills & operating costs

Depending on the EMS system you have in your store, you can keep tabs on whether your employees deploy these curtains at closing. If you are utilizing Singh360’s Worklist App, the pulling of curtains could be a task to remind personnel to deploy them.

Singh360 looks at the applicability of night curtains for your store and will identify cost, savings and ROI.

Case EC Motor Retrofit – Generally, shaded-pole motors are most commonly used by  OEMs for evaporator fan motors in refrigerated cases. Theshaded-pole motor is a type of single-phase AC induction motor. The reason OEMs use these is simple: they are simple in design, very readily available and the least expensive type of small, fractional horsepower motor available in the marketplace.

OEMs for evaporator fan motors in refrigerated cases. Theshaded-pole motor is a type of single-phase AC induction motor. The reason OEMs use these is simple: they are simple in design, very readily available and the least expensive type of small, fractional horsepower motor available in the marketplace.

EC motors, on the other hand, are brushless DC motors controlled by external electronics. EC motors are so efficient because they are electronically controlled and brushless, which means there is no friction on sparks generated.In a typical 50,000 sq.ft. grocery store you would generally see about 300 running at any given time. At 9 cents per kWh, a single typical evaporator fan will cost $53/year to operate. The same EC Motor would cost about $13/year to operate, which would provide grocers with sizable savings. The amp draw is only about about 17% of the OEM used fan motor, which brings about the savings. On top of this, the motors have a longer life.

Walk-In EC Motor Retrofit The same simple shaded-pole motors we discussed above, are used in  walk-in coolers or freezers and can be retrofitted with EC Motors to reduce the amp-draw and thus provide savings for the grocer. Many times you’ll find multiple evaporators in a walk-in and each have multiple evaporator fans. If you pay attention to these in your store, you’ll see that a few of them have failed and are no longer spinning. Rather than replace them with the same technology, why not test an EC motor and see how they perform for you? Engineers from Singh360 can easily show you the Amp-draw of a standard motor and have you compare it with an EC Motor. Singh360 can also help you look for rebates that your utility company may provide.

walk-in coolers or freezers and can be retrofitted with EC Motors to reduce the amp-draw and thus provide savings for the grocer. Many times you’ll find multiple evaporators in a walk-in and each have multiple evaporator fans. If you pay attention to these in your store, you’ll see that a few of them have failed and are no longer spinning. Rather than replace them with the same technology, why not test an EC motor and see how they perform for you? Engineers from Singh360 can easily show you the Amp-draw of a standard motor and have you compare it with an EC Motor. Singh360 can also help you look for rebates that your utility company may provide.

HVAC Energy Measures – It is vitally important that HVAC systems feeding your grocery store are in sync with the refrigeration equipment. If they aren’t, a lot of energy can easily be wasted. When engineers design your HVAC systems, they have design criteria and depending on the area of the country you’re in. They have a minimum temperature and a maximum temperature they design to, because they want to make sure the system is big enough to handle the extreme weather, should it arise. But did you know that almost 80% of the time the system doesn’t need this capacity, making for a wasteful operation, most of the time. But what can you do? The Engineers at Singh360 can help

Fan VFD–As mentioned above a VFD strategy can be deployed to reduce the airflow through the system when not needed. Considering the Affinity Law, a 10% reduction in motor speed of the fan can result in a 27% reduction in power drawn to drive the motor. Reducing the fan speed, will reduce the airflow, thus reducing gas usage in the winter and cooling in the summer. Tying this into your EMS system will provide further savings with more advanced strategies and give you insight into its operation.

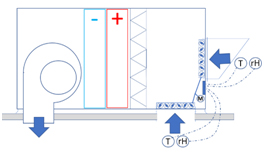

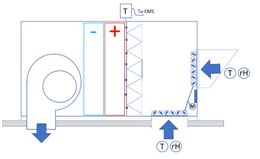

Economizer Optimization–When deployed properly, Economizers will provide free cooling when  the enthalpy (energy of the air) outside is lower than the enthalpy inside. The enthalpy of the air is a calculated value derived from the air temperature and humidity. If your economizers are based solely on air temperature, you can be creating a heavy cooling load at times that will cost more than if didn’t try to create this free cooling. The proper operation of your economizer is based on the proper measurement of temperature and humidity, both inside and out, the condition of the dampers, the function of the motor driving the damper and the linkage connecting the outside and return dampers to the motor. As you can tell, there are a lot of components making up this ‘free cooling’ and if anyone is not functioning properly waste can occur. Are you sure your economizers are functioning properly?

the enthalpy (energy of the air) outside is lower than the enthalpy inside. The enthalpy of the air is a calculated value derived from the air temperature and humidity. If your economizers are based solely on air temperature, you can be creating a heavy cooling load at times that will cost more than if didn’t try to create this free cooling. The proper operation of your economizer is based on the proper measurement of temperature and humidity, both inside and out, the condition of the dampers, the function of the motor driving the damper and the linkage connecting the outside and return dampers to the motor. As you can tell, there are a lot of components making up this ‘free cooling’ and if anyone is not functioning properly waste can occur. Are you sure your economizers are functioning properly?

Mixed Air Temperature Sensor – How do you know if your economizers are functioning properly?  The telltale sign is the mixed air temperature.This is a blend of the outside air and the indoor air and always so easily measured. There is no single point that you can measure so more often an averaging sensor is used with multiple sensors that are then averaged. What could throw off a mixed air temperature that would cause your system to cool or heat excessively?

The telltale sign is the mixed air temperature.This is a blend of the outside air and the indoor air and always so easily measured. There is no single point that you can measure so more often an averaging sensor is used with multiple sensors that are then averaged. What could throw off a mixed air temperature that would cause your system to cool or heat excessively?

- Linkage slippage

- Bent linkage

- Burned out motor

- Damper obstructions

- Defective controls

If any of the following happen, your HVAC system is working harder than it need to, which is wasting money. If monitored through an EMS, an alarm could trigger a malfunction, saving considerable operational costs.

Optimization of Humidity Control–Humidity levels in a grocery store are very important.  With high humidity, the evaporator coils tend to freeze up more from the condensation occurring. Doors on refrigerated cases also show condensation which makes it harder for the shopper to see what’s behind the glass door! Depending on store location, many Grocers will have large Dehumidification systems on their roof maintaining humidity levels. Many resort to controlling off of relative humidity, as its understood better. More astute operators control to dew point, which gives a better indication of the absolute water content in the air. Humidity control takes place in several of the grocers components:

With high humidity, the evaporator coils tend to freeze up more from the condensation occurring. Doors on refrigerated cases also show condensation which makes it harder for the shopper to see what’s behind the glass door! Depending on store location, many Grocers will have large Dehumidification systems on their roof maintaining humidity levels. Many resort to controlling off of relative humidity, as its understood better. More astute operators control to dew point, which gives a better indication of the absolute water content in the air. Humidity control takes place in several of the grocers components:

- Dehumidification unit

- Store HVAC systems

- Refrigerated door heater control

The engineers at Singh360 are capable of helping you in all three areas. Significant savings can be achieved if these systems are running independently and improperly maintained.

Control through Energy Management System – Depending on who and when your EMS system was installed, it may only be controlling a portion of your energy household. As mentioned before, systems need to work in harmony with each other, which therefore makes sense to control them with one system. Too often we’ve seen 4-5 different control systems working independently in a store. While each may work well on their own, if not coordinated they can easily fight each other, creating unnecessarily high energy bills.The engineers at Singh360 are capable of helping you evaluate the capability of your system and offer suggestions on bringing components together, under one control system.

LED Lighting – Practically every utility company is willing to provide you with incentives to install LED lighting to bring down the energy needs of your facility. These are straightforward replacements and easy to implement. We’d be surprised if you weren’t called at least once a week by a different company trying to sell you LED lighting. Everyone seems to be an expert! But buyer beware – they are not all the same. Look closely at the subtle but noticeable differences in color and appearance.

- Day light harvesting – If the electrical designed is planned properly, zones can be turned on and off when the sun is out, throwing light into the store. Significant energy can be saved by allowing mother nature to do her job. We look for windowed facades and domed sky lights can take the place of electrical lights.

Dimming – Dimming can be quite valuable for a grocery store. Lights can be dimmed…

- to indicate to store shoppers that the store is near closing time,

- when the store is not open, but some lighting is needed for stocking or cleaning,

- for security purposes

- to save energy and bottom line utility costs

Even dimming of low wattage LED lighting can be valuable and when integrated with an EMS become very flexible in its operation.

The engineers at Singh360 can show you how to apply dimming in your store.