Variable Frequency Drives in Refrigeration Equipment Deliver 1.5 to 5 Year Payback for Supermarkets

In this post you’ll see how variable-frequency drives (or VFDs) can generate a payback of 1.5 to 5 years in supermarkets. You’ll also see which uses of VFDs offer the fastest payback and highest return on investment (or ROI).

By Abtar Singh, President, Singh360 Inc.

How VFDs work

VFDs reduce electricity use by adjusting the speed of a fan motor to match its load. When HVAC or refrigeration equipment needs less airflow, VFDs reduces motor speed. They also increase motor speed when a unit needs more air.

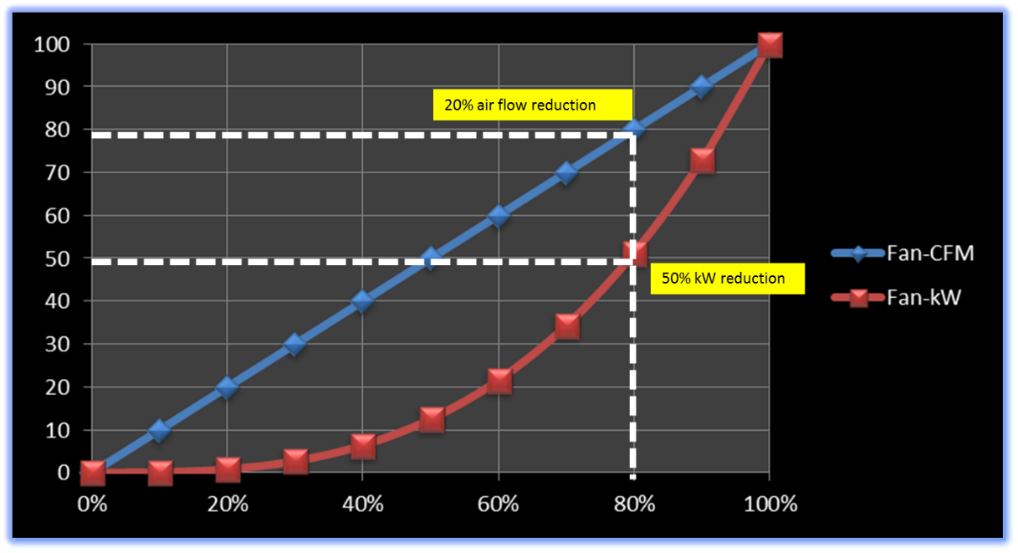

Fan power follows the cubic law or fan law. For example, when fan speed slows by 20%, power consumption falls by 50%.

Figure 1 shows the power savings you can achieve by switching to a VFD-controlled system. The figure shows general curves of percent loaded power versus percent loaded capacity.

Figure 1. Power savings achievable with VFDs

Payback periods for 6 supermarket uses of VFDs

Supermarkets can use VFDs in 6 ways. Each use offers a different payback period. The following list is arranged in order, with the fastest payback first:

1. Fan motors in HVAC blowers. Payback in 1.5 years or less. The typical supermarket has one or two big HVAC units to serve the sales floor. It also has many small rooftop units (or RTUs) for offices and departments.

In our experience at Singh360, HVAC blower fans of more than 7.5 horsepower typically provide the fastest payback and best ROI. Many HVAC units (including the Seasons4 units) have a vestibule, and you can locate a VFD inside the unit.

The payback for such systems can be less 1.5 years without utility rebates. But if the VFD is mounted outside the unit, you’ll need a NEMA-3 enclosure. (See Figure 2.) That extends the payback to 2.5 to 3 years.

Figure 2. VFDs in an HVAC system (NEMA-3 enclosure)

2. Fans in refrigeration condensers. Payback in 2 to 3 years. Many supermarkets have rack systems with air-cooled or water-cooled condensers. The condensers may have from 6 to 10 fans with motors of 1.5 horsepower each. The combined horsepower of the fans may range from 9 to 15.

VFDs generate savings through the fan law, and they can also reduce head pressure if you configure EMS system for “floating head pressure” control.

The payback range varies from 2 to 3 years, depending on whether the VFD needs a NEMA-3 enclosure.

3. Kitchen hood exhaust and make up air fans. Payback in 3 years. When supermarkets cook food locally, they need exhaust and makeup fans for their stoves and ovens. Cooking patterns vary throughout the day and night, but exhaust and makeup fans typically run all the time.

You can save fan power as well as heating and cooling energy by putting a VFD on a hood exhaust as well as make up air fan. With the VFD in place, you can vary the speed of the fan based on cooking activity. Figure 3 shows use of a VFD with an exhaust fan in a kitchen hood.

Typical payback for use of VFDs on hood fans and makeup air fans is 3 years, not including rebates.

Many gas and electric utilities offer attractive rebates. For example, Singh360 retrofitted 8 stove hoods with a Halton demand control ventilation system for a Minnesota supermarket. The retailer collected a rebate of about $40,000 from the electric utility and about $10,000 from the gas company. (Disclosure: Singh360 represents Halton Americas for supermarkets.)

Figure 3 VFD installation in a kitchen hood exhaust fan

4. Motor room exhaust fans. Payback in 1.5 to 5 years. The compressor room or motor room in a supermarket typically has exhaust fans to keep its temperature below 90 degrees Fahrenheit. Motor rooms are usually in the back of a store. If they aren’t properly sealed off, their exhaust fans suck conditioned air from the store. The fans also create negative air pressure in the store, pulling untreated air through the front entrance. As the untreated air moves past refrigeration units, it may cause their doors to sweat and evaporator coils to ice up.

If the fan motors are less than 1.5 horsepower, it may not make sense to use VFDs in a motor room. But the cost of VFDs is coming down for motors with less horsepower, so it may be worth putting in a VFD to control the temperature in motor the room.

5. Refrigeration compressors. Payback in 1.5 to 5 years. For compressor motors, VFD power follows a linear function rather than a cubic fan law. Even so, VFDs can help reduce compressor cycling and increase life of contactors and compressors.

Supermarkets often have oversized refrigeration racks. They may not use their full capacity in winter when the cooling load is lighter. In such cases a single compressor is likely to have plenty of capacity for the evaporator load. If a rack has hot-gas defrost, a compressor is forced to keep running (even if load is matched) so that hot gas can be provided for defrost.

In such situations, VFDs can save a lot by reducing rack power. VFDs also save money by reducing inrush power when compressors start running. When a system becomes stable, you can often get additional savings by raising suction pressure (or float). Figure 4 shows a VFD installation with refrigeration compressors.

The payback of 1.5 to 5 years varies with the system you install.

Figure 4 VFD application in compressors

6. Boiler Pumps. Payback in 1.5 to 4 years. If a supermarket uses hot water for heating zones and baseboard heaters, you can use VFDs in boiler pumps to match load and flow. This is an ideal way to save energy on both pump power and boiler heat.

Getting your money back

Many utility companies offer excellent prescriptive rebates for use of VFDs. For example, Xcel Energy provides rebates based on motor horsepower. For a 10-horsepower motor their rebate is about $1,000. For a 20-horsepower motor it’s about $1,600. Often you can get even better rebates through a custom incentive application.

For most applications, the distance between the VFD and the motor is important. If the distance is more than 100 ft., you may increase the life of the motor by adding a filter. For motors smaller than 5 horsepower, it’s better to use a VFD-graded motor.

At Singh360, we’ve found that HVAC blower fans of more than 7.5 horsepower typically provide the best ROI. The next-highest return comes from using VFDs in refrigeration condenser fans with motors totaling more than 7.5 horsepower.

Use of VFDs in refrigeration compressors delivers the smallest reduction of energy consumption. But such applications can reduce compressor cycling and extend the life of compressors. And that’s worth real money too.

About Singh360

Singh360 Energy software and services range from building-envelope assessments to complete design of mechanical and electrical systems (including HVAC, lighting and refrigeration systems) for new and existing buildings using mobile and cloud app from kWh360 Inc.

These innovations help organizations set priorities for efficiency projects based on sustainability goals, speed of payback, and the measured return on investment. Contact Singh360 to see if these innovations fit with your facility and energy management strategy going forward.

Interested in a demo?

Contact us at info@singh360.com