Use of Variable Frequency Drives Cuts on HVAC Blower Cuts Energy Use by 45%

Singh360 leads project that helps Lunds & Byerly’s stores achieve payback estimated at 1.5 years. The use VFD drives cuts energy usage by 45% in their stores

Maple Grove, MN: Use of variable-frequency drives (or VFDs) enabled Lunds & Byerly’s grocery stores to cut energy use by almost half in blower-fan motors at five locations. This is according to Abtar Singh, chief executive officer of Singh360, a firm that provides energy-management services to grocery supermarkets.

Singh360 helped design and implement VFDs at Lunds Holdings, Inc. (or LFHI). Lunds operates 22 upscale supermarkets under the banners of Lunds & Byerly’s. The project involved a total of 10 blower fans, with two in each of the five stores.

How VFDs Save Energy

More than 95% of all installations of heating, ventilation and air-conditioning (or HVAC) systems in the United States use single-speed motors rather VFDs”, Singh estimates. VFDs save energy by running electric motors at variable speeds. They control the speed of the motor by changing the frequency or voltage of the alternating current (or AC) on which it runs. “When you reduce the speed of a fan motor by 20%, air flow decreases by 20%,” Singh said. “But energy use drops by 50%.”

What the VFDs Accomplished at Lunds

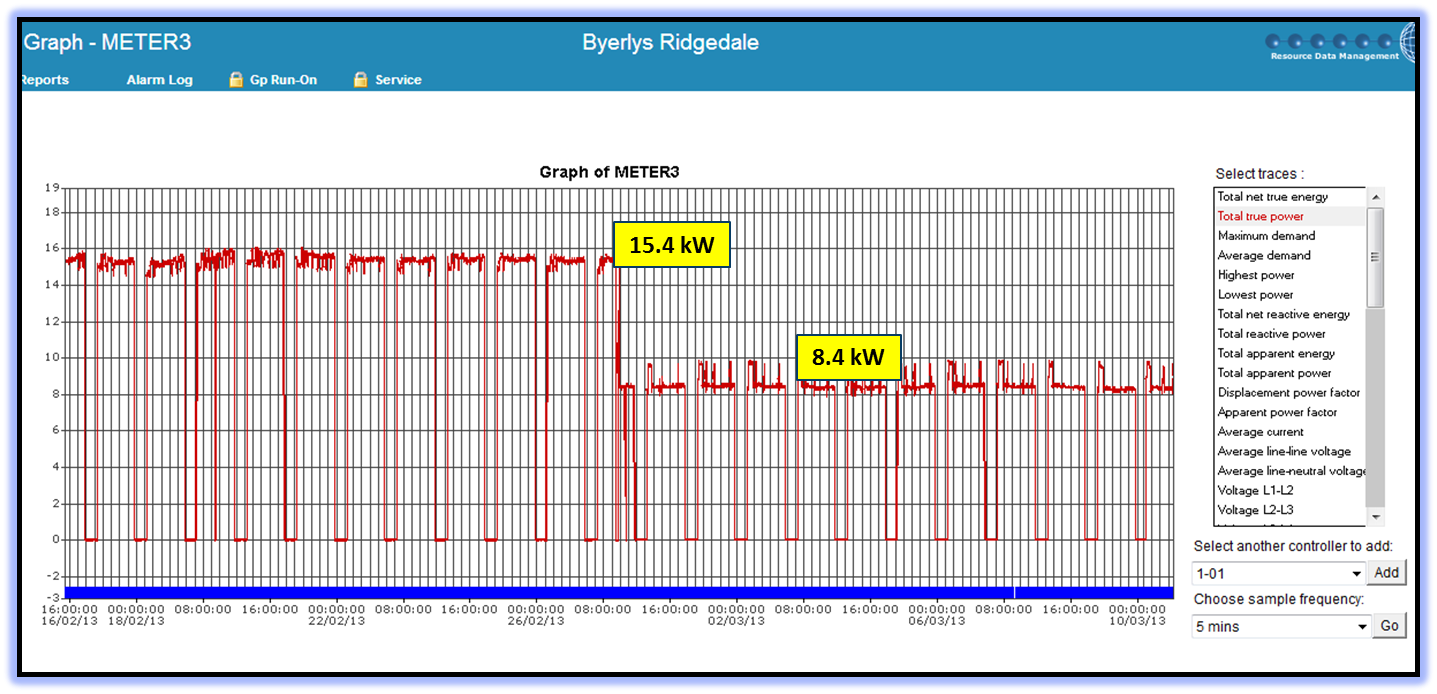

The graph below shows before-and-after energy use for a single VFD installation in a Byerly’s store, recorded by an energy-monitoring system. For single-speed motors, energy use ran at about 15.4 kilowatt-hours. Then the introduction of VFDs dropped energy consumption to 8.4 kilowatt-hours. The reduction for this one store was 45.5%.

Average energy reduction for the project was 45% across all five stores.

VFD reduced energy consumption by 45.5% for one installation.

The average reduction was 45% across 10 motors in five stores.

Payback in Less Than Two Years

“We expect to see full payback on our investment in installing the VFDs in a range of one to two years,” said Wally Lindeman, facilities maintenance manager at LFHI. “That’s very solid performance, in our view.”

Importance of Proper Installation and Maintenance

“But you can’t just install these drives and be done with them,” Lindeman said. “You have to train your service technicians to be sure they’re properly maintained. Without proper training, technicians will bypass the VFD in a future service call.”

“Singh360 did a top-notch job. They not only commissioned the changes to our systems,” Lindeman said, “but they also trained our internal and external service technicians in how to maintain the VFDs. And they implemented a technology to alert our building-management system if anyone tries to bypass the VFDs.”

The successful use of VFD technologies requires some special engineering in grocery stores,” Singh said. “You have to pay close attention to air flow in the service area. You have to be careful to avoid causing your cooling compressors to flood. You also have to watch for over-temperature tripping of heating units. And in grocery, you must pay special attention to food quality in the dairy, produce and fresh-foods sections. You have to watch both air flow and humidity.”

VFDs for Other Grocery Applications

In addition to using VFD in blower fans for HVAC systems, Singh says grocers can further reduce energy consumption by using VFD technology in the condenser fans and compressors of refrigeration systems.

“VFDs make the operation of refrigeration systems smoother. If you implement them with the proper control strategy, they can reduce power consumption by 20% to 30% in those units,” Abtar Singh said.

VFD from a Local Source

Control Technique, a business unit of Emerson Electric in Eden Prairie, Minnesota, built the VFD used in the project. Each drive can operate with either a Modbus or a BACnet interface. These protocols enable them to communicate with most current building-management systems.

“We’re happy to have worked with Singh360 on this project for Lunds,” said Jim Chmielewski, program manager at Emerson Control Technique. “The project demonstrates the opportunity for additional cost reduction in many grocery retailers.”

###

About Singh360

Singh360 Energy software and services range from building-envelope assessments to complete design of mechanical and electrical systems (including HVAC, lighting and refrigeration systems) for new and existing buildings using mobile and cloud app from kWh360 Inc.

These innovations help organizations set priorities for efficiency projects based on sustainability goals, speed of payback, and the measured return on investment. Contact Singh360 to see if these innovations fit with your facility and energy management strategy going forward.

Interested in a demo?

Contact us at info@singh360.com